Explore the benefits of implementing a professional SPI inspection today

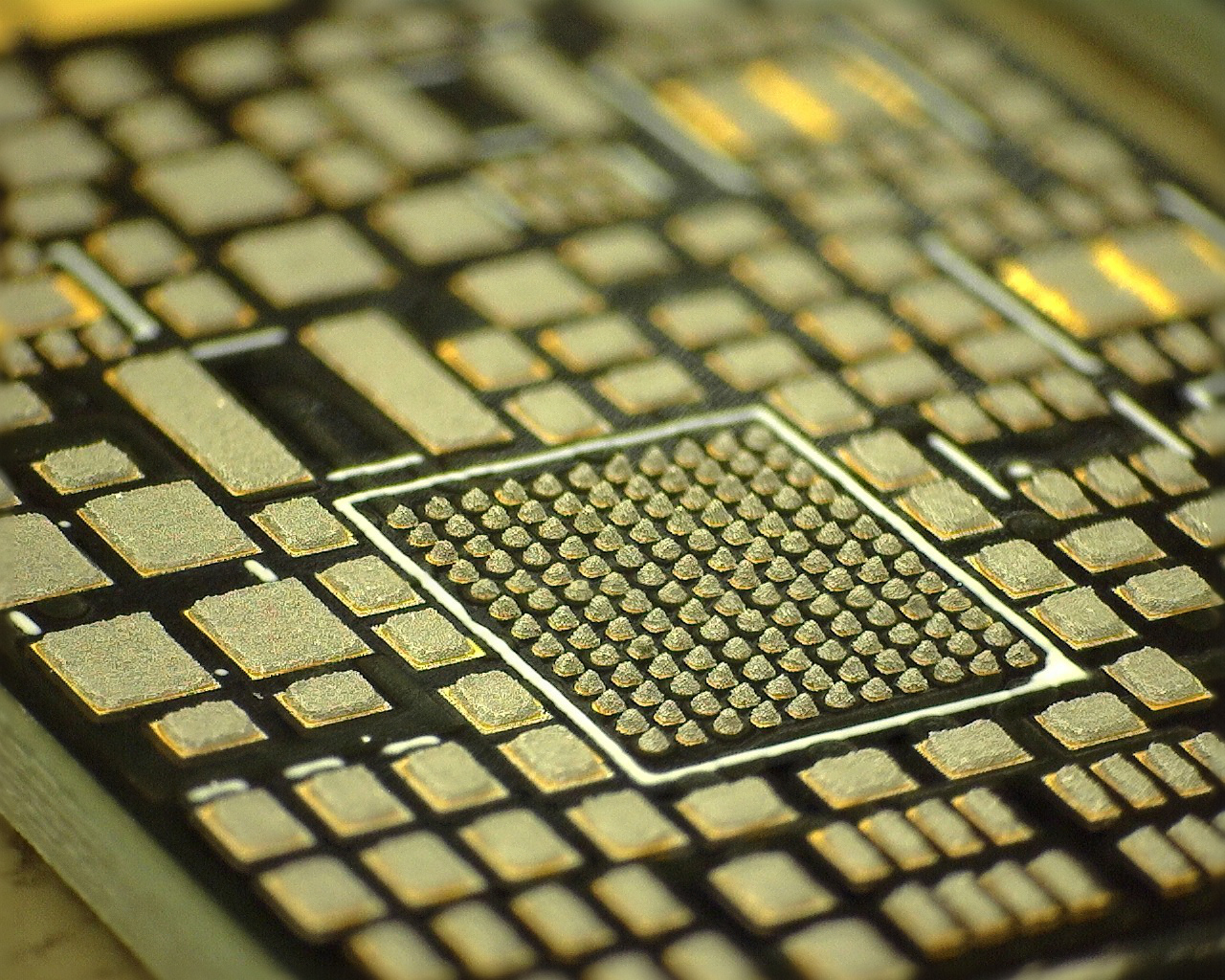

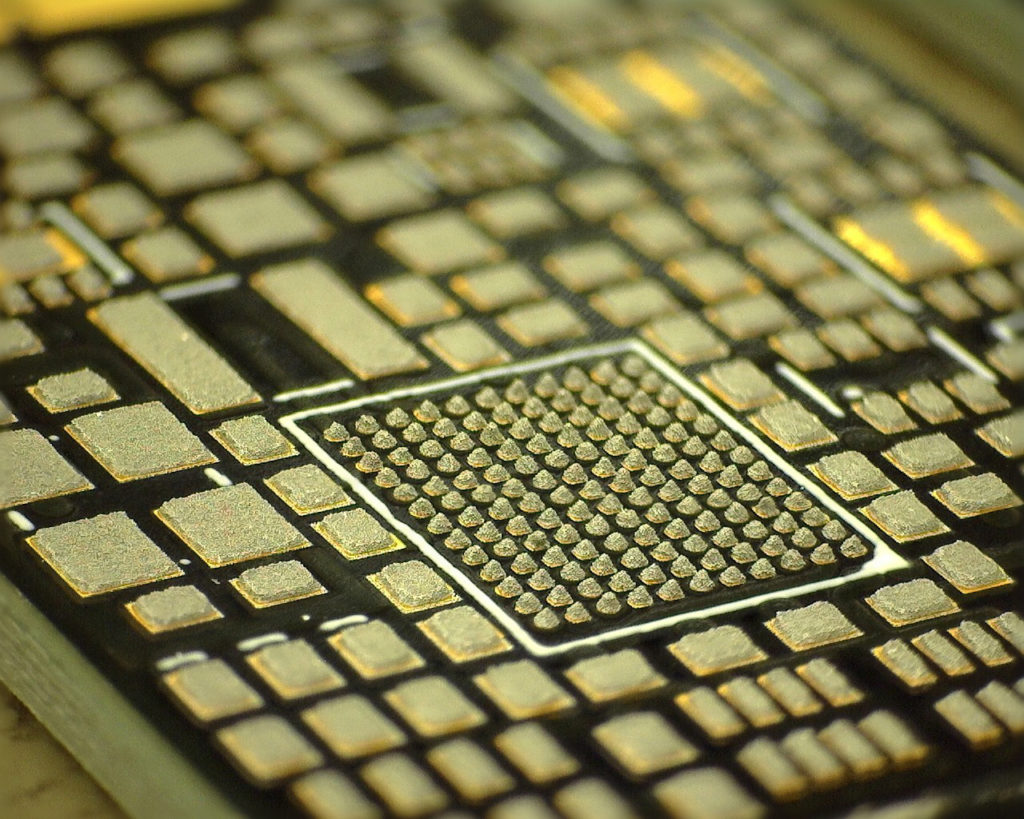

In April 2022, we installed a new solder paste inspection (SPI) device on our SMT shop floor. The installation of the SPI was preceded by a multi-hour selection process, part of which involved ongoing tests of equipment from various manufacturers.

Why is the use of SPI (Solder Paste Inspection) of great and growing importance to customers of EMS service providers? The simple explanation that it is about quality is not enough, as there is a quality objective in the background of almost every investment in machinery.

The last two years have been a particularly difficult time for electronics manufacturers. The confluence of natural catastrophes and the COVID-19 pandemic, the breakdown of supply chains and even political tensions and armed conflicts have not favoured electronics manufacturers, who are experiencing shortages in the availability of electronic components.

Today, when customers can’t afford the risk of faulty PCBAs, as the components wasted in a faulty assembly process may not be available for many months, when we consider that up to 60% of defects in SMD assembly can be attributed to the paste printing process, the quality dimension of the investment in SPI is paramount.

Read more in our article about the investment carried out and the benefits it brings>>