Final assembly of devices

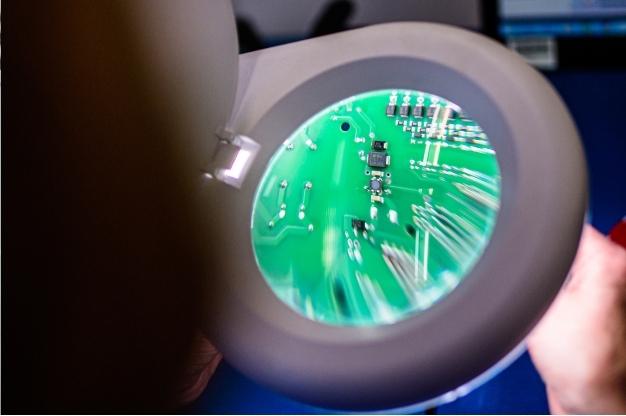

Many customers started their collaboration with an EMS partner with a printed circuit board assembly (PCBA). However, it turned out that a good cooperation can extend to further areas of device fabrication.

Depending on a specific situation, we carry out for our Customers:

- IC programming on a PCBA;

- ICT and FCT tests;

- connecting PCBAs into pre-assembled units;

- potting, conformal coating;

- assembly of electronic boards into enclosures and EOL (end of line) tests;

- reliability testing;

- final quality inspection and sealing in transport or sales packaging;

- delivery to customer or drop shipping (delivery directly to a logistics centres or even to the end customer).

We have delivered several million units in the drop shipping model. Our contract manufacturing customers trust us and the assembled devices are sent directly to the market. They still find this to be a great solution.

In accordance with our customers‘ preferences, we take over from them the responsibility for providing the packagings, plastic housings, metal parts, etc.

For our customers we can be the key to the market of local suppliers of plastic and metal parts, packagings manufacturers. Our company is located in the industrial centre of Poland, in Silesia.

In order to ensure that the assembled PCBs or devices are delivered to the customer undamaged, we develop suitable packaging and shipping methods.

We ensure that packaging is appropriately labelled according to the customer’s guidelines, identify the contents of each package, and ensure that packaging materials comply with current environmental regulations.

When the end customer reports a failure to our client we act as the factory repair centre, verifying the claim and classifying it, repairing or replacing it.