Technical basis for quality assurance in PCBA manufacturing – a process approach in EMS practice

Quality assurance in electronics manufacturing is not a one-off activity, but a complex and multi-step process. Decisions taken long before the first assembly cycle – as early as the design stage, the selection of components or the establishment of final inspection methods – are crucial.

- Why does PCBA quality start even before production?

- How to avoid errors before they occur?

- Why is full traceability so crucial?

- What is the importance of advanced SMT assembly and 3D AOI inspection?

- Which tests are crucial for your device?

- How do you choose an electronics manufacturing outsourcing (EMS) partner that ensures not only on-time, but also an optimal level of quality?

In this article, we discuss how the various links in the contract manufacturing value chain translate into repeatable PCBA quality, and why the meticulousness and experience of an EMS partner should be considered a strategic factor.

Why supplier selection is strategic

In 2023, the aviation world was shaken by a case involving the supply of engine components for Airbus A320 and Boeing 737 aircraft with false technical documentation. The investigation revealed as many as 78 cases of falsified certificates. Although there were no reported incidents involving these components, the industry responded with a rapid check of records and intensive cooperation with regulators.

The case demonstrates the huge risks of inappropriate supplier selection. Even a single unverified partner can expose a company to catastrophic image and financial losses. Regardless of the sector in question, supplier selection should be treated not as a logistical step, but as an element of strategic quality management on which the success of the entire project depends.

Design for manufacturability – DFM analysis as a foundation for serial quality

One of the key aspects affecting the subsequent reliability of an electronic assembly (PCBA) is design with assembly realities in mind. The practice of Design for Manufacturing (DFM) allows solutions that may cause technological difficulties or increase the risk of errors to be identified at the design documentation review stage.

In the contract manufacturing process, DFM involves verifying the design in terms of component placement, distances between components and compliance with the requirements of assembly and inspection machines. Too little spacing can cause technological problems during assembly or optical inspection, while incorrect placement of test points can prevent ICT testing. Such issues are identified at the initial analysis stage, even before production starts, thus avoiding costly corrections, unexpected delays and the risk of stopping the assembly process. The aim of the analysis is to simplify production, reduce costs and ensure the highest possible quality of the final product.

As JM elektronik’s practice shows, carrying out a reliable DFM analysis makes it possible to reduce the risk of errors already in the first production run, reducing implementation time and eliminating the need for costly corrections.

This topic is discussed in more detail in the article:

DFM analysis reduces the risk of errors during production>>

Component distribution experience as a guarantor of a transparent supply chain

The physical quality of components has a direct impact on the reliability of the entire PCBA assembly. In unstable supply chains, the risk of using components from unauthorised sources, stored in inadequate conditions or counterfeits is a significant risk. A manufacturing partner with extensive sourcing and material logistics expertise has a significant advantage in terms of quality.

JM elektronik has been active in the distribution of electronic components for more than 35 years. Through its partnerships with manufacturers of semiconductors, passive SMD components and connectors, the company has direct access to certified supply channels, which minimises the risk of counterfeit or aftermarket components. This enables full component traceability and ensures compliance with quality standards and regulations, such as REACH and RoHS directives.

Importantly, the distribution experience also translates into better flexibility to propose replacements in situations of market shortages and better purchase planning for long-term stability.

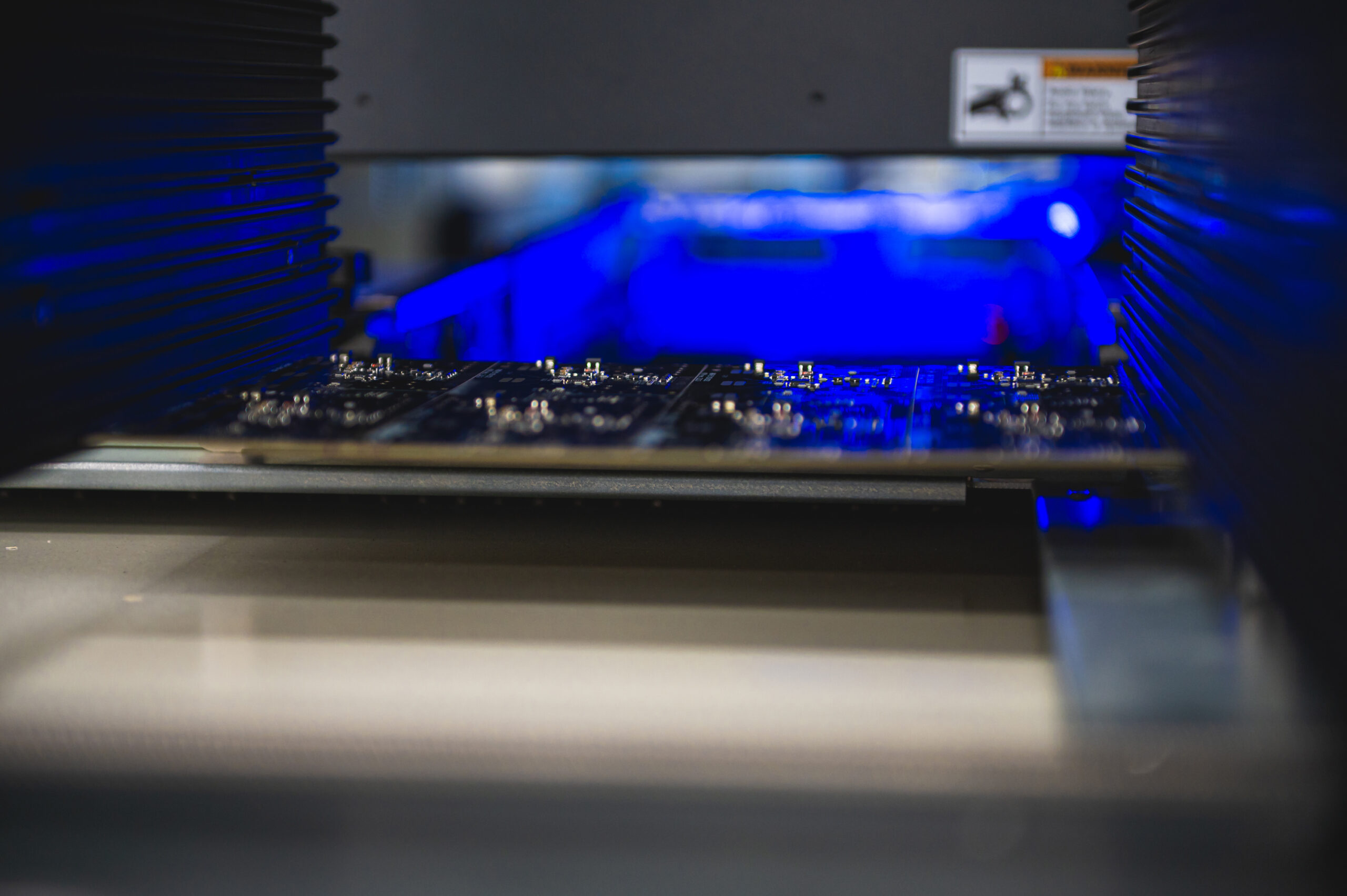

SMT assembly and optical inspection – quality verified in real time

The surface mount assembly (SMT) process is one of the most sensitive stages of PCBA production. The high packing density, miniaturisation of components and variety of enclosures require precise machines and, at the same time, sophisticated inspection tools.

JM elektronik uses SMT assembly lines equipped with state-of-the-art Yamaha pick-and-place machines in the assembly process, with a total capacity of more than 110,000 components per hour. The uniform and logically consistent configuration of the individual production lines allows for optimised distribution of orders across the lines, resulting in greater flexibility and reduced lead times.

In the SMD assembly process, the solder paste application process is critical to quality. Precise, state-of-the-art paste printers are supported by an SPI machine that controls in 3D the effect of the paste application even before the components are laid down. This ensures that defects are prevented right at the start of the process. After the reflow soldering process, the components are subjected to an automatic 3D optical inspection (AOI), which, unlike 2D inspection, enables a 3D analysis of the solder joints, identifying shortcomings, bridges, offsets or incorrect component orientation.

The advantage of AOI 3D systems is the ability to create statistical quality models to identify defect trends, which translates into continuous improvement of the assembly process.

Find out more: AOI 3D at the service of quality control>>

Optical inspection cannot detect all types of defects – especially those related to invisible internal damage, breaks in connections or electrical irregularities. Therefore, electrical and functional tests are an important supplement to the quality control process.

JM elektronik uses an appropriate combination of testing methods, ranging from in-circuit tests (ICT), HiPot safety tests, automated functional tests (FCT), sometimes carried out in climatic chambers. Each of these methods is applicable depending on the characteristics of the system.

Which test is best for your PCBA – a comparison of ICT and flying probe>>

The HiPot test, which involves applying a high voltage between paths or insulated layers, can detect micro-punctures, improper galvanic separations and potential electrical hazards to the end user. This is particularly important in mains-powered products.

HiPot tests on offer at JM elektronik>>

Automatic functional testers (FCTs), on the other hand, make it possible to run a device under near-target conditions – with power supply, input/output signals and communications. This makes it possible not to check selected functionalities of the manufactured assembly or device.

Summary – quality as an engineering and organisational value

High quality PCBA manufacturing is not the result of a single stage or technology – it is the sum of consistently executed activities that include product design, purchasing, logistics and warehousing processes, quality control plan design, assembly, testing and final inspection. The key is the process approach and the competence of the organisation at each of these levels.

Companies using EMS services should pay attention not only to price and lead time, but also to operational quality – the availability of DFM competence, supply chain transparency, inspection technologies and final testing capabilities. The experience of the EMS partner, its competence and technical background, and its ability to identify risks early have a direct bearing on the final reliability of the product.

As an experienced contract manufacturer, we take responsibility for the quality of the equipment entrusted to us, which is why at JM elektronik we attach the same importance to every part of the production process. We have been cooperating with many customers for several years. Companies satisfied with our services commission us to produce the next generation of their devices.

Take advantage of our experience and see how we can help you.