PCBA production cost – what it depends on and how we optimise it at JM elektronik

The cost of contract electronics manufacturing is one of the key factors determining the success of a project. Customers often focus on delivery times, assembly quality, and component availability, but it is equally important to understand how the cost of PCBA production is calculated and which elements have the greatest impact on it.

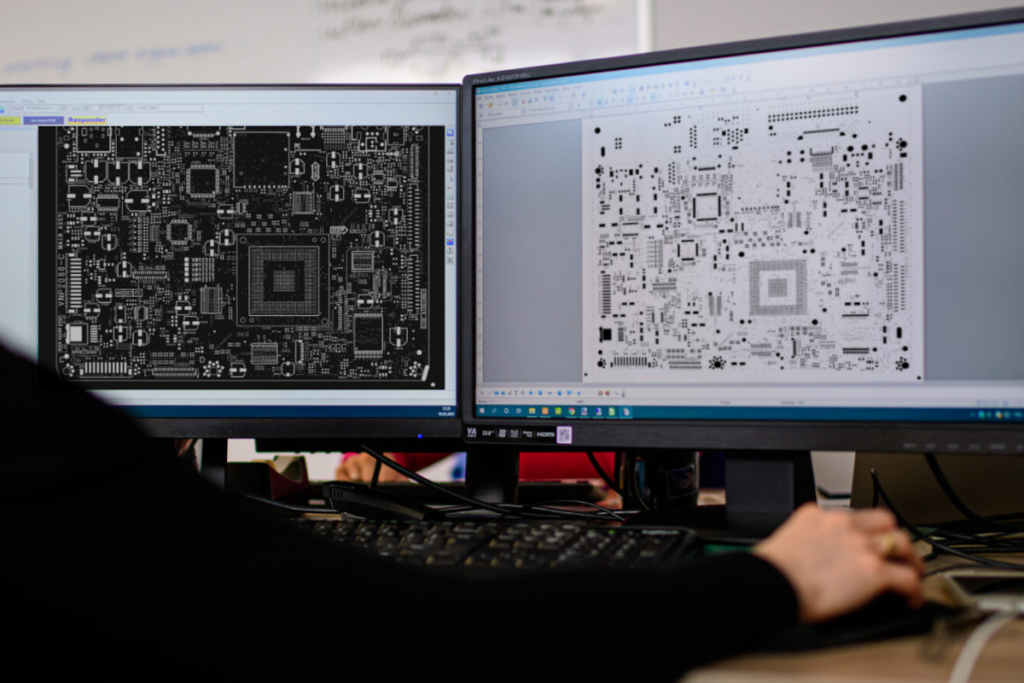

At JM elektronik, we carefully analyse each stage of the process – from PCB design and component sourcing to assembly and testing – to ensure our customers receive the best value for their investment. In this article, we present the most important factors affecting PCBA production costs and explain how we support our partners in optimisation.

Before the first component reaches the production line, costs begin to build up at the PCBA design stage. The more complex the design, the higher the price. A multi-layer board with thin tracks, manufactured from a specialised laminate designed for high frequencies, involves completely different expenses than a standard double-sided FR-4 board. Each additional feature, such as extra layers, plated edges, or gold-plated connectors, automatically increases the cost of production.

The size and layout of the PCB itself are equally important. Standard production panels have fixed dimensions, so an unusual board shape or a format that prevents full utilisation of the available space leads to material waste and therefore raises the unit cost.

Another factor influencing the budget is labour-intensive assembly. Introducing advanced components, often necessary in innovative designs, requires more precise and expensive machines and sometimes mandatory X-ray inspection. Furthermore, any operations that cannot be automated require additional manual work or the use of dedicated tools, which further increases total production costs.

Electronic components often represent the largest share of the production budget. Their price depends on the type of components used, their technological complexity, and the current market situation.

The prices of microcontrollers, memory chips, and even basic capacitors can rise sharply due to global shortages. Another challenge involves production and delivery lead times, which may increase as a result of unexpected disruptions. The market experienced this particularly during so-called allocation periods, which is why it is so important to secure a stable supply chain in times of dynamic fluctuations in semiconductor availability.

Order size also matters – for smaller quantities, especially when ordered below the factory packaging size, the unit price can increase significantly, illustrating the classic example of economies of scale. Final costs are also affected by factors such as packaging methods: if the packaging is unsuitable for automated assembly, manual preparation becomes necessary, which generates additional expenses.

Optimising PCBA costs is not about finding savings at each stage of production individually, but rather about taking a strategic approach to the Total Cost of Ownership (TCO). TCO includes all expenses related to a project or product throughout its lifecycle – not only the purchase price, but also costs of design, production, logistics, maintenance, testing, servicing, and risk management.

The greatest potential for cost reduction appears before production even begins – at the design stage. This is why applying Design for Manufacturing (DFM) principles and involving an EMS partner early in PCB development are crucial.

Standardisation is a key element of cost control. Choosing the same resistors, capacitors, and diodes across the design simplifies procurement, reduces machine setup times, and minimises the risk of errors. It is also advisable to design boards to fit standard production panels, which maximises material utilisation and reduces waste.

The cost of PCBA production also depends largely on the assembly technology used. SMT (surface-mount technology) is faster, highly automated, and more cost-effective for larger production volumes. THT (through-hole technology), on the other hand, is more time-consuming and often requires manual labour, which increases the price. For highly complex projects, we use hybrid solutions combining both approaches.

At JM elektronik, our engineers support customers by recommending minor design adjustments that can significantly simplify assembly and reduce final costs. We have described this topic in more detail in our article on DFM analysis>>

Production strategy also plays a significant role. Prototype manufacturing is relatively expensive because it requires individual line preparation, additional testing, and full process configuration. In the case of small series, the unit cost also remains high, but with larger orders, it is spread across a greater number of units, which significantly reduces the price.

Whenever possible, it is worth simplifying processes – for example, by consolidating smaller orders into larger batches, which allows for more efficient use of economies of scale.

The cooperation model with an EMS provider should also be carefully chosen. For large and stable projects, the turnkey model, where the EMS partner is responsible for the entire process, is usually the most cost-effective. However, for prototypes or when the customer provides their own components, a consignment model may be a better solution.

Testing is another important factor. Instead of aiming for maximum inspection in every case, it is worth assessing the optimal level of testing for a given product – sometimes AOI (Automated Optical Inspection) is sufficient, while for medical devices, full functional and high-voltage testing is often necessary.

Investing in a well-designed process that prevents errors is often more cost-effective than detecting them at later stages when corrections become significantly more expensive.

The choice of production location has a significant impact not only on cost but also on quality and process security. Manufacturing in Asia may initially seem cheaper, but it often involves limited quality control, longer delivery times, and a greater risk of intellectual property infringement.

Looking at the process as a whole, a low unit price does not always translate into real savings, as potential rework, complaints, and delays can substantially increase the final project cost.

Short lead times require additional resources, both for component procurement and production line scheduling, and they limit opportunities to optimise purchasing strategies, which negatively impacts final costs.

That is why careful planning is so important. Together with our customers, we prepare tailored production schedules to minimise the costs of urgent orders and avoid unnecessary risks related to time pressure.

The cost of electronics production results from a combination of many interrelated factors: design, components, assembly technology, batch size, testing requirements, production location, and certifications.

At JM elektronik, we ensure that every stage of the process is optimised and that our customers receive full cost transparency. Thanks to our experience, flexibility, and individual approach, we help bring products to market faster, safer, and more efficiently.